CONTROL CABINETS:

DESIGNED TO PERFOM, BUILT TO LAST

Our cabinets are world class, built with true European craftsmanship to international standards such as NEN60204. With regular maintenance, they will last a minimum of 20-25 years and we use only recognised brands for our components (Siemens, Schneider and Phoenix Contact). This means that spare parts can be sourced locally and quickly in an emergency, helping you to avoid downtime and breakdowns. Our feed mill experts calculate the cooling of the cabinets – for example, by maintaining the correct temperature (if the ambient temperature is too high, the life of the components is drastically reduced).

FIELD INSTALLATION

Our cabinets are intelligently designed to operate with a minimum of components. However, installing and setting up this technology can be complex. That’s why you can rely on Inteqnion’s experienced engineers to get you up and running. Our engineers have handled many installations, always in compliance with EMC regulations and profiNET connections. For example, it’s important to achieve a distortion-free field installation for accurate measurements and reliable data connections.

ATEX

Explosion protection is extremely important in feed mills. The dust from raw materials can cause serious explosions. Our engineers are trained to the latest regulations.

SIL

We care about the safety of your people. Production equipment can be very dangerous if the necessary protection is not taken. Our design complies with the SIL” safety standard.

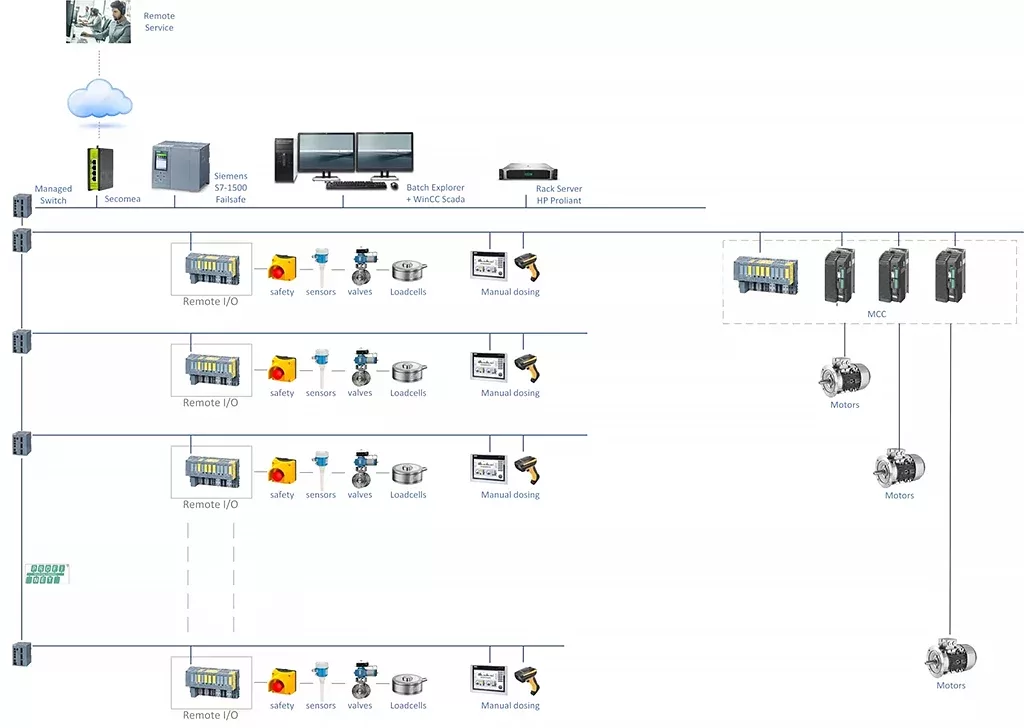

IP based automation is the gateway to smart industry

Our solution is completely based on PROFINET, the industrial Ethernet for real-time communication. It is extremely reliable and even safe for safety applications. With remote VPN access, it gives us the maximum service level to access the lowest level in the factory. The amount of data we can collect from each piece of equipment opens the way to intelligent industry.

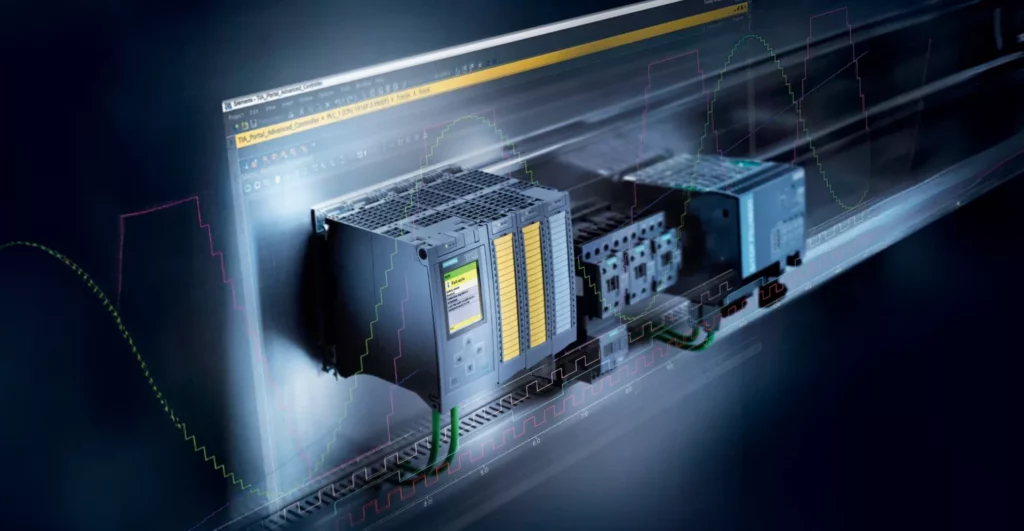

PLC Hardware

Our automation solution is based on a Siemens S7-1500 PLC.

We prefer a Siemens Safety PLC to achieve a high level of safety and flexible design.

Our remote I/O and variable speed drives are connected via PROFINET for maximum serviceability and reliable communication.

Local Controls

To operate from the production floor we design local touch panel applications. Easy to use with Scada or BatchExplorer functionality.

- For pellet press and extruder control

- Intake and outloading

- Scanner applications for tipping points