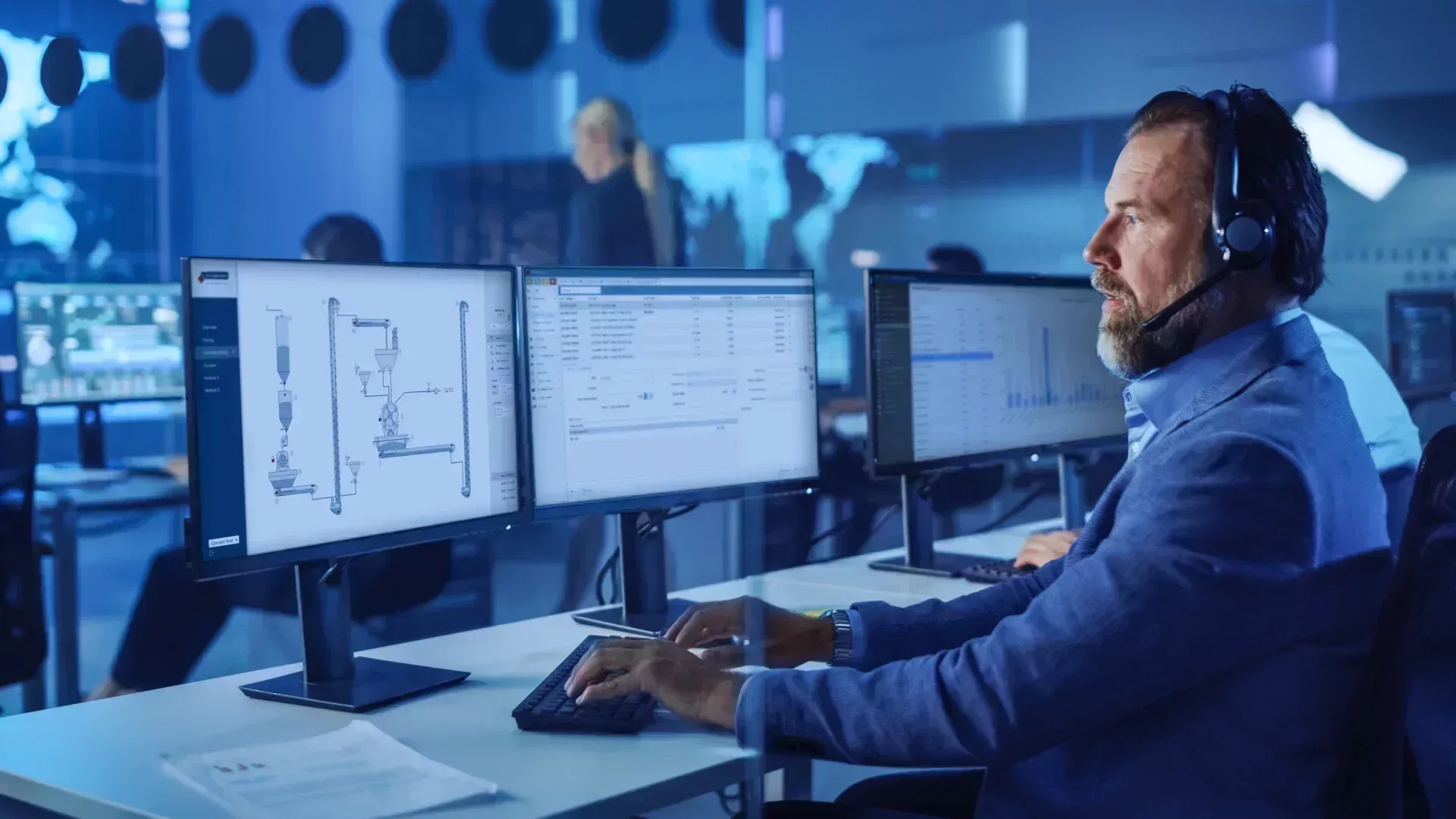

Turnkey process control for feed production

Our solution provides comprehensive control of feed production, from order-to-order to outloading. We have consolidated all the knowledge and insight gained from our 250 installations worldwide to create a user-friendly software suite that can be optimised remotely, delivering high-quality output at the lowest operational cost. This is true data-driven milling, designed to futureproof your operation. The system is straightforward to operate in the field and can be optimised remotely.

Create the highest output quality

Datadriven milling is the the key to achieving your goals

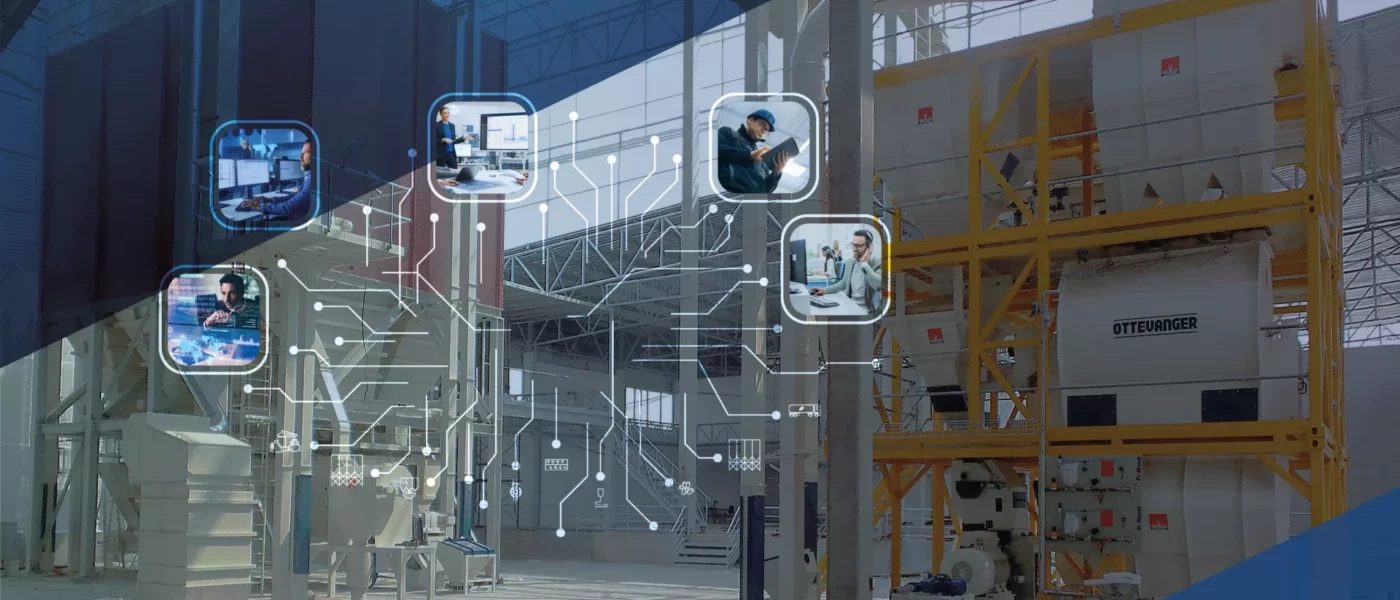

The concept of data-driven milling is simple. Our lives are now completely IP connected. Why not apply the same principle to the feed mill? At Inteqnion we achieve this through a software suite that connects the plant at strategic, tactical, operational and production levels. We can collect and use data at every stage – including cloud-based data from sister feed mills. Using our software, your people can then make smarter, more informed and objective decisions that enable the feed mill to run more smoothly, efficiently and cost-effectively.

Inteqnion’s Milling Software Suite

Inteqnion feedmill automation software is designed to take your milling to the next level by connecting your operation at every level. We offer you cutting-edge & extensively tested software: all based on the finest European engineering.

Cloud Dashboard - Strategic Level

Strategic dashboarding for Asset Management, Maintenance, OEE and Energy.

Batch Explorer - Tactical Level

Get full control over the factory on tactical level. Based on datadriven milling and powerful batch processing. Designed with and for feed mills.

Scada - Operational Level

Control the plant at the operational level with a modern graphical interface. Easy to operate with advanced settings and diagnostics.

Field Tools - Production Floor Level

Control details from the shopfloor with local operator panels, mobile devices and scanner systems.

Cloud Dashboard - Strategic Level

Cloud Dashboard - Strategic Level Batch Explorer - Tactical Level

Batch Explorer - Tactical Level Scada - Operational Level

Scada - Operational Level Field Tools - Production Floor Level

Field Tools - Production Floor Level

Motor Control Centers

& Field Installation

Designed and build for many years reliable production

Choosing the right hardware is essential for any feedmill – because it’s the heart of the automation solution.

We design, build and maintain your hardware to enable the smooth running of systems – while avoiding any downtime in case of emergency or breakdown.

We use worldwide brands for our electrical components – which can be sourced locally when spare parts are needed fast.

More than 250 installations worldwide

More than 250 user worldwide rely on the control system of Inteqnion. We keep close contact to every user to continuously improve our system.