GAIN FULL CONTROL OF YOUR FEED MILL

For years, our Batch Explorer MES software has helped customers of all shapes and sizes improve the speed and efficiency of their production at various stages (intake/outloading, pelleting and – of course – batching). Designed and continually improved using the insights of more than 250 feed mills worldwide, this single-source software is configured to meet the needs of your specific feed mill – making it extremely robust and easy to upgrade.

Production with less operators

Our intelligent software is designed to operate as much as possible without human intervention. Optimised settings for recipes and production orders are used for the next production. Intelligent algorithms contribute to consistent production quality.

Full control for quality and performance

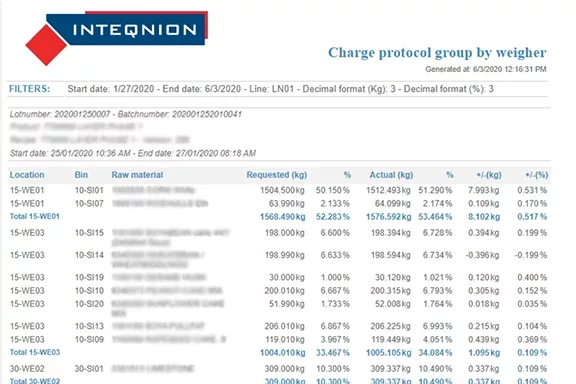

Local Reporting

Batchexplorer includes many standard reports such as batch reports, dosing accuracy.

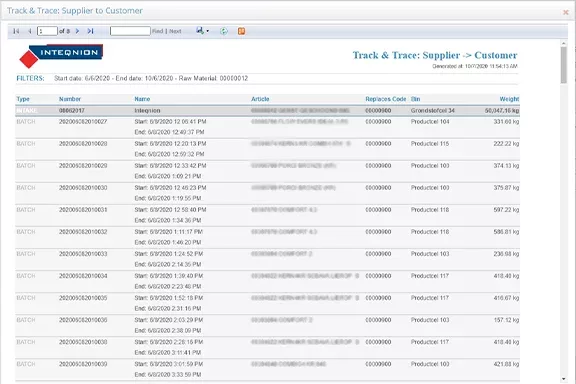

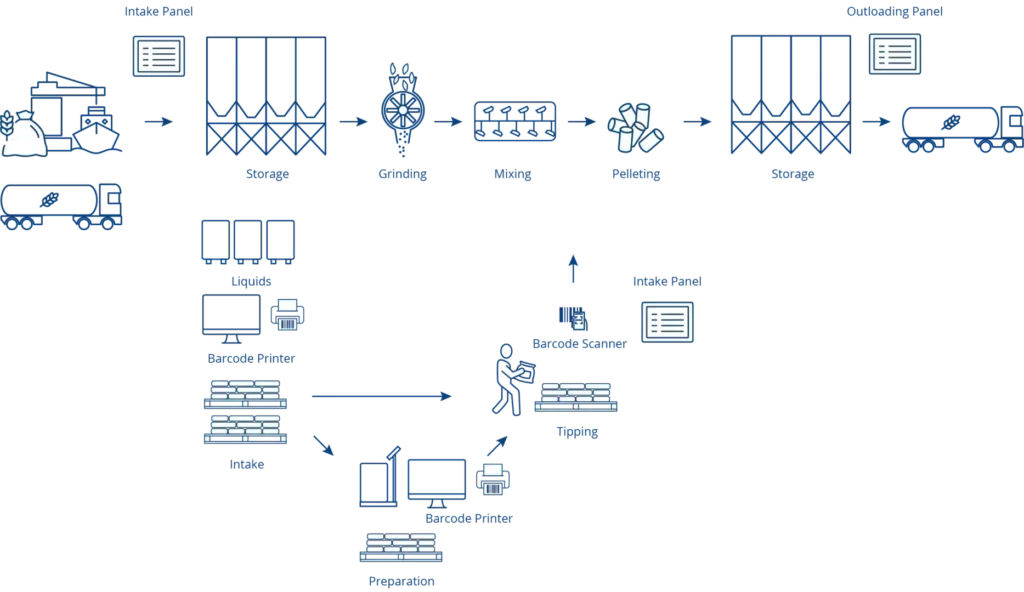

Track & Trace

Tracking raw materials is important. BatchExplorer keeps track of where it has been used in production and to which customers it has been sent. Generate useful reports in case of raw material problems.

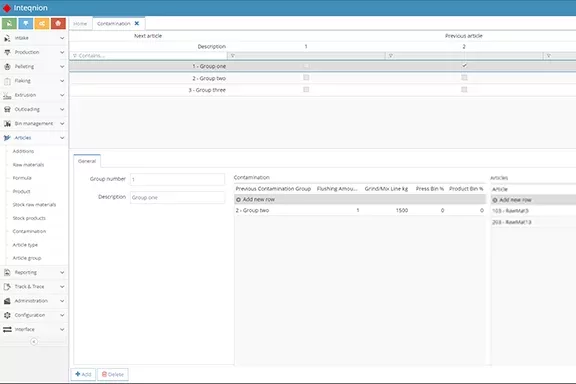

Contamination

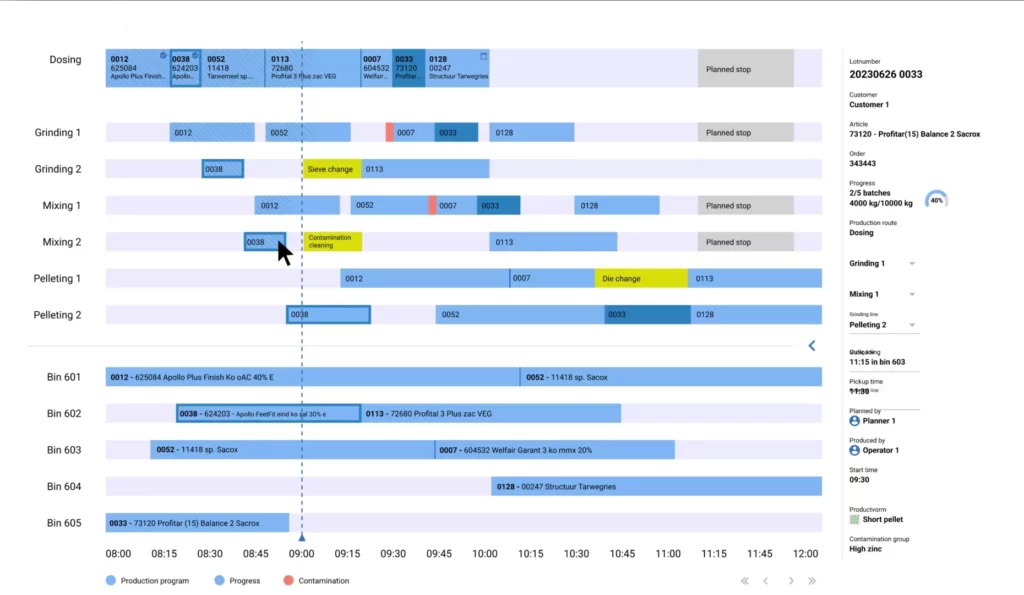

Contamination is extremely important in feed production. Easily create advanced configurations. BatchExplorer takes care of this during production.

Intelligent Planning

Plan production in a Gantt chart and see the result in the production sections. See contamination, screen and die changes and make decisions.

Secure intakes with barcodes

Produce the right product with the right input at the right time with our foolproof barcoding systems. Not only do these systems minimise the potential for error, they also provide invaluable track and trace functionality. Our barcode systems even include a preparation station for ultra-low volume and manual dosing.

Import/Export interface

The paperless feed mill is now a reality for many of our customers. To achieve this, simply use our universal data interface (based on XML, DataBase or restAPI).

The power of batch processing

By collecting – and connecting – critical information at every stage of your feed mill production process, Batch Explore enables your team to make objective, data-driven decisions at a tactical level.

INTEQNION’S MILLING SOFTWARE SUITE

Inteqnion feedmill automation software is designed to take your milling to the next level by connecting your operation at every level. We offer you cutting-edge & extensively tested software: all based on the finest European engineering.

Cloud Dashboard - Strategic Level

Strategic dashboarding for Asset Management, Maintenance, OEE and Energy.

Batch Explorer - Tactical Level

Get full control over the factory on tactical level. Based on datadriven milling and powerful batch processing. Designed with and for feed mills.

Scada - Operational Level

Control the plant at the operational level with a modern graphical interface. Easy to operate with advanced settings and diagnostics.

Field Tools - Production Floor Level

Control details from the shopfloor with local operator panels, mobile devices and scanner systems.

Cloud Dashboard - Strategic Level

Cloud Dashboard - Strategic Level Batch Explorer - Tactical Level

Batch Explorer - Tactical Level Scada - Operational Level

Scada - Operational Level Field Tools - Production Floor Level

Field Tools - Production Floor Level