Why Inteqnion services?

For many years, feedmills worldwide have relied on the Inteqnion team & technology to achieve reliable production – with minimal downtime and maximum output.

Our scalable feedmill automation solutions enable you to futureproof your operation (lasting a minimum 20-25 years). But this is really just the start. It’s our proven Services that really enable you to get the very most value from this technology – and your investment.

Our experienced team is available to support you every step of the way, wherever you are: with everything from operator training; to diagnosing production hiccups and bottlenecks; to providing emergency maintenance and spare parts.

Read on to learn how…

Keeping your software up-to-date

At Inteqnion, we understand that to get the very most from your automation software, it’s essential to keep it up-to-date – and therefore enable your operation to keep pace with the changing demands of the feedmill environment. Because every one of our customers’ installations is safely backed-up on our virtual servers, the Inteqnion team is able to test all software updates in advance, in a controlled environment – ready for a fast and efficient installation at your facility. Ultimately, while software updates are never mandatory, they remain a key part of our Service offering.

Our aim is to provide you with the best feed mill automation software solution in the world. We listen to our customers and keep our knowledge up to date according the latest software technology. We have a great software development team and work according Scrum method to deliver a high quality.

Keep your feedmill 24/7 up

and running with maximum

preformance for many years

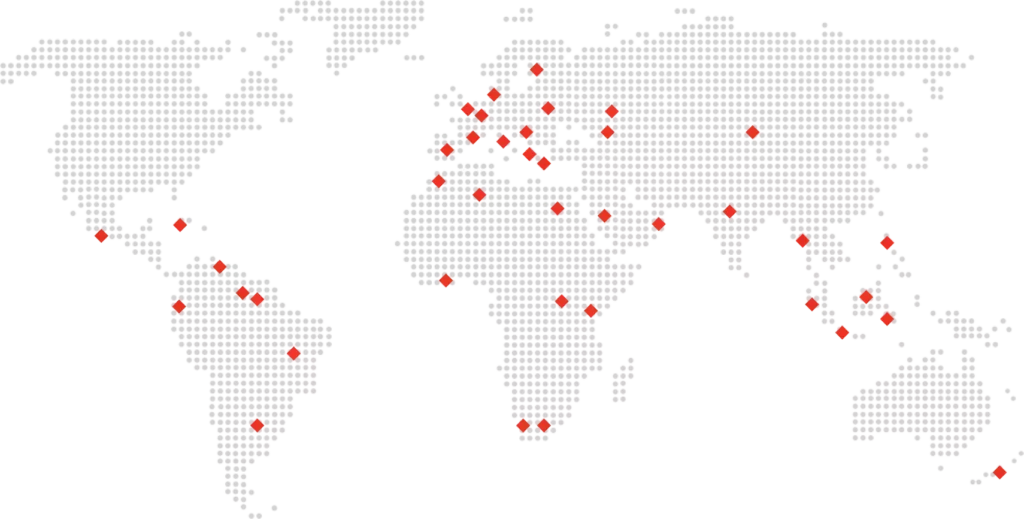

More than 250 installations worldwide

More than 250 user worldwide rely on the control system of Inteqnion. We keep close contact to every user to continuously improve our system.

Operator education & training

Technology is only as good as the people using it. At Inteqnion, we want you to get maximum value from our solution; but we also understand the challenges that feedmills increasingly face in attracting, training and retaining qualified operators.

Over the years, our service team has helped operators worldwide improve both their understanding of our software and their subsequent ability to utilize it in diagnosing and solving problems on the factory floor. This includes everything from increasing tonnage to improving pellet hardness, to reducing the number of production alarms, to training in the latest software updates.

Maintaining your hardware with our annual IT health check

When it comes to maintaining your hardware, our philosophy is that prevention is better than cure. As your feedmill changes, so too do the technology demands placed upon it – which in turn requires updates and modifications of mechanical, electrical and software systems. Our annual IT health check is a service contract that ensures you stay ahead of any hardware issues. We can clean-up old data to speed up your system; as well as installing and configuring software remotely.

Service visit:

an extra pair of eyes

Many technical challenges can be handled remotely by our service professionals (via a shared screen). But sometimes only an in-person visit will do.

Our experts are always available to visit your facility and bring a wealth of feedmill experience that enables you to get more from your existing assets, whether it be process, equipment, people – or all three.

Whatever your technology challenge, the Inteqnion team has almost certainly seen it (and solved it!) before.

Sourcing your spare parts

Our cabinets are build with world class components from major brands. Normally these components can be sourced worldwide. Inteqnion has a lot components on stock and can be delivered quickly. Our Team can also advice which components are better to have locally in your factory on stock. This will reduce the downtime in case of emergency dramatically.

Inteqnion can also deliver the field components like sensors, loadcell and touchpanels. We can per-installs software on touchpanels, plc’s and other IT equipment.

Our design of the cabinets and fields installation is based on a minimum of variation on components and a maximum of diagnostics on each level.

Location

Inteqnion B.V.

Weverij 2

7122 MS Aalten

Nederland

KvK: 09.171.676 te Arnhem

BTW: NL. 8183.94.237.B.01